Environmental Footprint Research

WorldBag Reconditioning Service

Minimising our impact

on the environment

As a responsible company with our own production facilities, we worry about natural resources running out.

Our contributions

In our daily operations, LC Packaging has a direct impact on Global Sustainable Development Goals (SDGs) 8,9, 12 and 17 as set by the United Nations. However, we are committed and proud to contribute to even more of the SDG's through our actions and initiatives.

Environmental footprint research

Environment

Back to top

Scroll down

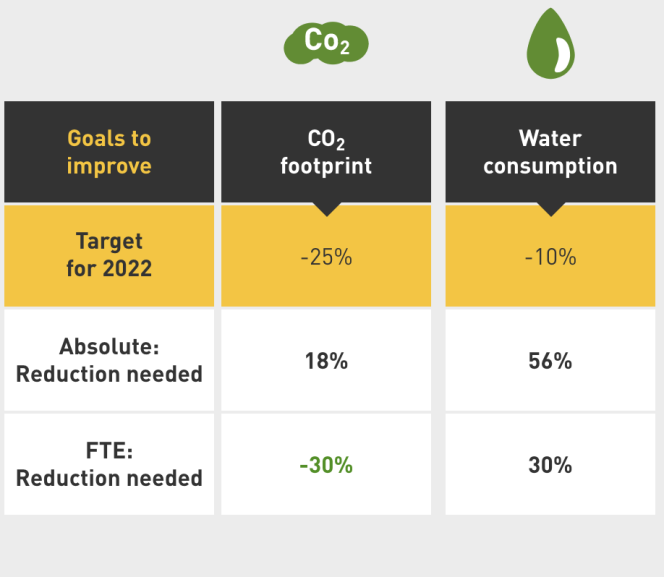

LC Packaging, aided by Except Integrated Sustainability, conducted comprehensive corporate environmental footprint research of our CO2 emissions, waste generation and water and energy use in 2020.

Every year, an environmental footprint research is conducted by Except Integrated Sustainability to understand more about our impact, monitor our use of resources and identify areas in which we can improve or use recourses more efficiently. LC Packaging conducted its very first environmental footprint research in 2016. Based on the outcomes of this research, we finalised our environmental targets for 2022. Since 2016, we have increased our workforce by 59%, added an extension to our production facility in Bangladesh and scaled up our production worldwide. In 2020, we have started

the construction of a third extension. Naturally, all of this has caused our CO2 emissions, energy use and water consumption to increase. The reductions brought about by our initiatives to minimise our water and energy use and Co2 emissions so far do not outweigh these developments. Our initiatives related to reducing our waste production however, have contributed to us already reaching our 2022 target. Our GREENBangla in-house process waste recycling initiative in particular has made a huge impact. 29% of all our waste produced worldwide is recycled in-house.

Goals to

improve

Target

for 2022

Absolute: Reduction needed

FTE:

Reduction needed

There are several impactful initiatives on the calendar for the upcoming year. A co-generation system and a high capacity solar plant for example. In 2020, LC Packaging’s production facility in Bangladesh Dutch-Bangla Pack Ltd. (DBPL) also became a signatory of the Science Based Targets Initiative (SBTi) to further reduce its emissions in line with climate science.

In 2020 we have launched our Green Office Campaign with the ultimate goal to further reduce our joint consumption of water, waste and energy and our CO2 footprint and to contribute to our 2022 environmental goals. LC Packaging offices, warehouses and production facilities participate in the campaign and have each received their own targets, tailor-made to its situation.

When all locations achieve their goals, it will show a huge impact on our environmental footprint. Additionally, a maximum amount of €20,000,- will be donated to local initiatives and organisations benefitting the environment by the LC Supports Foundation.

Sustainable solutions 2020: 103-1, 103-2, 103-3

Global Goals

Goals offices and warehouses

HQ Carbon negative

Today, 55% of electricity used by LC Packaging is coming from renewable sources, of which 36% is self-generated. 19% is purchased renewable electricity from the grid. This has a positive impact on our CO2 emissions. However, if we look at our overall energy use - which does not solely include electricity but also fuel (mostly gas) and company owned vehicles - we only make use of renewable recourses for 7.5% of which 4.9% is self-generated. We are already looking at improvements we can make in these areas.

More data in our 2020 Environmental Report

Renewable energy and electricity

LC Packaging’s new head office in Waddinxveen was built with sustainability in mind. Innovative measures have been taken to minimise CO2 emissions and the consumption of energy and water. On the roof for example, 3,032 solar panels have been installed, generating enough energy to supply 386 households for a full year. Rainwater is collected and cleaned using a special roof-membrane and used by nearby horticultural businesses so no water is wasted unnecessarily.

In 2020, the new office reached a carbon negative status, because it produces more renewable energy with the help of its solar panels then it uses. That renewable energy is delivered to the grid. With this negative CO2 footprint, it compensates the CO2 emissions of many other affiliates.

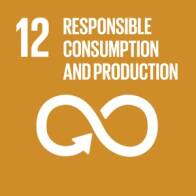

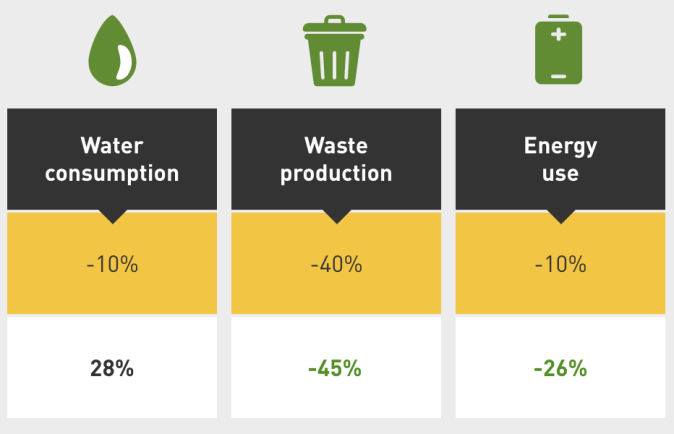

3 Goals achieved

When we look at the environmental footprint of solely LC Packaging offices and warehouses, we have (over)achieved 3 of the 4 goals we have set; CO2 footprint, waste production and energy use. Of course we are fully aware that LC Packaging’s environmental impact lies largely at our production facilities. However, we do also feel that every bit helps and many colleagues put time, effort and dedication into achieving local goals. Reducing water consumption remains a challenge. Even though most of our employees have not been at the office much in the past year due to the COVID-19 regulations, we still used more water compared to 2016. We need at least a 28% decrease by 2022 to reach our 10% reduction goal.

Goals to

improve

Target

for 2022

Absolute: Reduction needed

WorldBag Reconditioning Service

Environment

Back to top

Scroll down

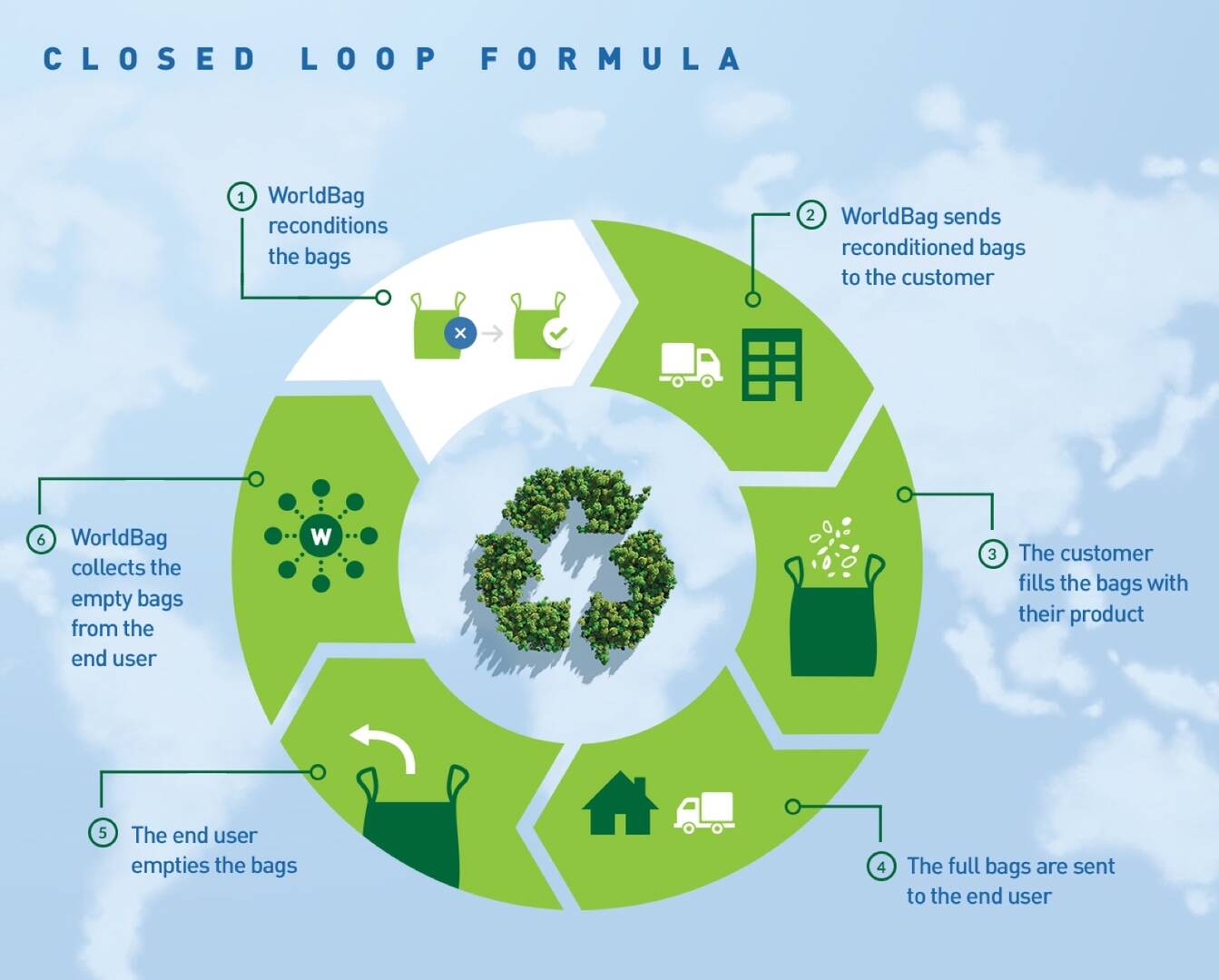

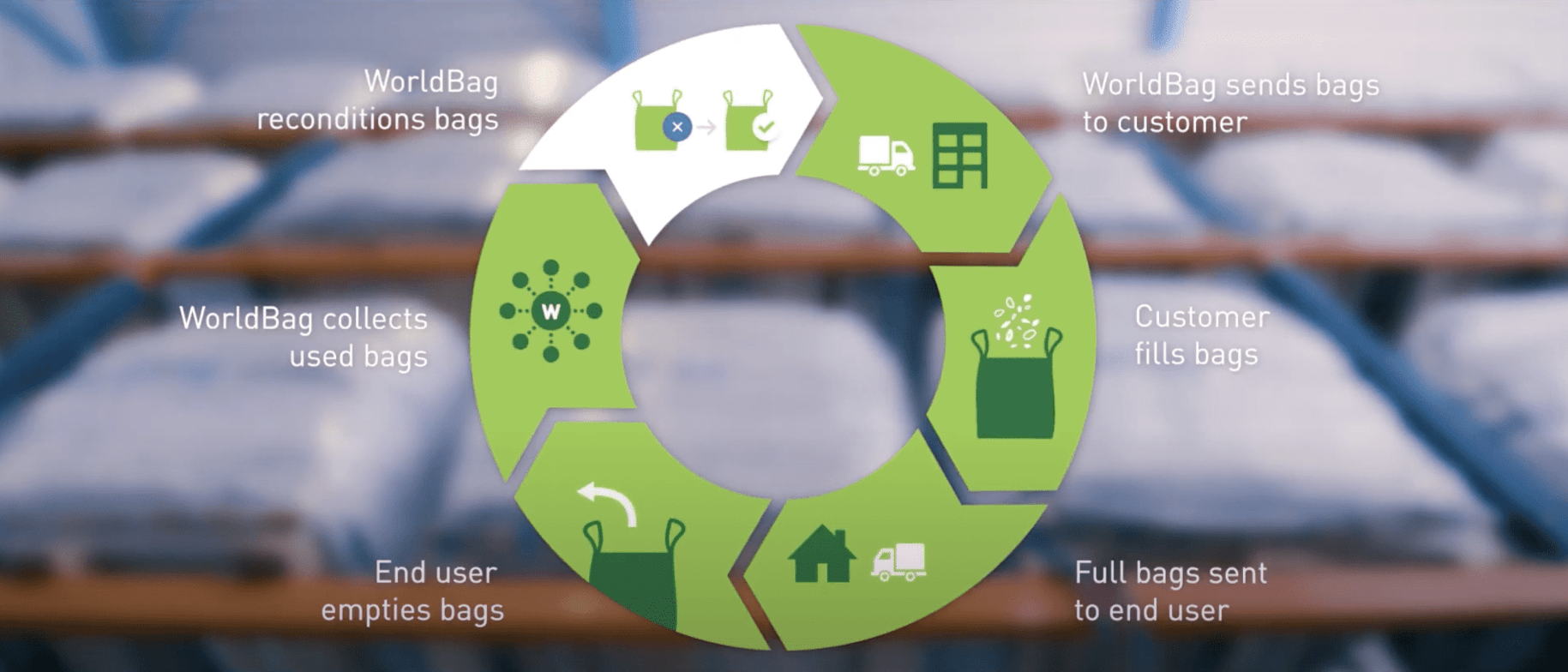

WorldBag is specialised in reconditioning and

recycling big bags.

Reuse your big bags

WorldBag specialises in the reconditioning of big bags (FIBCs) and making them fit for reuse. WorldBag collects used big bags all over Europe at our customers’ or end-users’ locations. We are reconditioning (cleaning and repairing) them and deliver them back to our customers to be reused again; filled with products, emptied and picked up again for reuse. With this closed-loop formula, WorldBag offers a unique, efficient and 100% sustainable solution with the right balance between a long lifespan and low costs. It leads to a 43% - 66% reduction in the carbon footprint of the FIBC, depending on the number of reuse cycles. When reusing an FIBC 5 times, you save:

LC Packaging research shows that 55% of the European big bag consumption is reusable. This translates to 77 million bags per year! Today, 28 million FIBCs are already reusable and there is a strong reuse potential for another 49 million big bags in the near future.

Currently, less than 4% of FIBCs are reconditioned. In 2020, LC Packaging reconditioned approximately 50,000 big bags through our WorldBag reconditioning service. This is not enough. That is why we have generated more commercial attention to its possibilities and advantages by organising an informative webinar about the benefits of reuse as part of our Sustainable FIBC Virtual Conference.

By reconditioning 50,000 FIBCs in 2020, we were able to save up to 440,000 L if water, 285,000 kWh of energy, 120,000 kg of raw materials and 555,000 kg of CO2.

www.worldbag.com

More data in our 2020 Environmental Report.

Sustainable solutions 2020: 103-1, 103-2, 103-3

49 mln

28 mln

Potential for reuse in numbers

current vs. future

28 mln current potential

49 mln future potential

'Closing the loop'

Benefits of reconditioning

Minimising environmental footprint

Sustainable solution in waste management

Cost savings

Minimisation of costs for disposal/incineration

(External) Customer loyalty

Possible bag recycling

-> circular program LC / Veolia

Protection against reputation damage

Reporting on reuse and environment impact

Strong potential for reuse

As a responsible company with our own production facilities, we worry about natural resources running out.

Minimising our impact

on the environment

Environmental footprint research

Target

LC Packaging, aided by Except Integrated Sustainability, conducted comprehensive corporate environmental footprint research of our CO2 emissions, waste generation and water and energy use in 2020.

Every year, an environmental footprint research is conducted by Except Integrated Sustainability to understand more about our impact, monitor our use of resources and identify areas in which we can improve or use recourses more efficiently. LC Packaging conducted its very first environmental footprint research in 2016. Based on the outcomes of this research, we finalised our environmental targets for 2022. Since 2016, we have increased our workforce by 59%, added an extension to our production facility in Bangladesh and scaled up our production worldwide. In 2020, we have started the construction of a third extension. Naturally, all of this has caused our CO2 emissions, energy use and water consumption to increase. The reductions brought about by our initiatives to minimise our water and energy use and Co2 emissions so far do not outweigh these developments. Our initiatives related to reducing our waste production however, have contributed to us already reaching our 2022 target. Our GREENBangla in-house process waste recycling initiative in particular has made a huge impact. 29% of all our waste produced worldwide is recycled in-house.

There are several impactful initiatives on the calendar for the upcoming year. A co-generation system and a high capacity solar plant for example. In 2020, LC Packaging’s production facility in Bangladesh Dutch-Bangla Pack Ltd. (DBPL) also became a signatory of the Science Based Targets Initiative (SBTi) to further reduce its emissions in line with climate science.

Our contributions

In our daily operations, LC Packaging has a direct impact on Global Sustainable Development Goals (SDGs) 8,9, 12 and 17 as set by the United Nations. However, we are committed and proud to contribute to even more of the SDG's through our actions and initiatives.

Sustainable solutions 2020: 103-1, 103-2, 103-3

Global Goals

In 2020 we have launched our Green Office Campaign with the ultimate goal to further reduce our joint consumption of water, waste and energy and our CO2 footprint and to contribute to our 2022 environmental goals. LC Packaging offices, warehouses and production facilities participate in the campaign and have each received their own targets, tailor-made to its situation.

When all locations achieve their goals, it will show a huge impact on our environmental footprint. Additionally, a maximum amount of €20,000,- will be donated to local initiatives and organisations benefitting the environment by the LC Supports Foundation.

3 Goals achieved

When we look at the environmental footprint of solely LC Packaging offices and warehouses, we have (over)achieved 3 of the 4 goals we have set; CO2 footprint, waste production and energy use. Of course we are fully aware that LC Packaging’s environmental impact lies largely at our production facilities. However, we do also feel that every bit helps and many colleagues put time, effort and dedication into achieving local goals. Reducing water consumption remains a challenge. Even though most of our employees have not been at the office much in the past year due to the COVID-19 regulations, we still used more water compared to 2016. We need at least a 28% decrease by 2022 to reach our 10% reduction goal.

Goals offices and warehouses

HQ Carbon negative

LC Packaging’s new head office in Waddinxveen was built with sustainability in mind. Innovative measures have been taken to minimise CO2 emissions and the consumption of energy and water. On the roof for example, 3,032 solar panels have been installed, generating enough energy to supply 386 households for a full year. Rainwater is collected and cleaned using a special roof-membrane and used by nearby horticultural businesses so no water is wasted unnecessarily.

In 2020, the new office reached a carbon negative status, because it produces more renewable energy with the help of its solar panels then it uses. That renewable energy is delivered to the grid. With this negative CO2 footprint, it compensates the CO2 emissions of many other affiliates.

Renewable energy and electricity

Today, 55% of electricity used by LC Packaging is coming from renewable sources, of which 36% is self-generated. 19% is purchased renewable electricity from the grid. This has a positive impact on our CO2 emissions. However, if we look at our overall energy use - which does not solely include electricity but also fuel (mostly gas) and company owned vehicles - we only make use of renewable recourses for 7.5% of which 4.9% is self-generated. We are already looking at improvements we can make in these areas.

More data in our 2020 Environmental Report

WorldBag Reconditioning Service

Reuse your big bags

WorldBag is specialised in reconditioning and

recycling big bags.

WorldBag specialises in the reconditioning of big bags (FIBCs) and making them fit for reuse. WorldBag collects used big bags all over Europe at our customers’ or end-users’ locations. We are reconditioning (cleaning and repairing) them and deliver them back to our customers to be reused again; filled with products, emptied and picked up again for reuse. With this closed-loop formula, WorldBag offers a unique, efficient and 100% sustainable solution with the right balance between a long lifespan and low costs. It leads to a 43% - 66% reduction in the carbon footprint of the FIBC, depending on the number of reuse cycles. When reusing an FIBC 5 times, you save:

LC Packaging research shows that 55% of the European big bag consumption is reusable. This translates to 77 million bags per year! Today, 28 million FIBCs are already reusable and there is a strong reuse potential for another 49 million big bags in the near future.

Currently, less than 4% of FIBCs are reconditioned. In 2020, LC Packaging reconditioned approximately 50,000 big bags through our WorldBag reconditioning service. This is not enough. That is why we have generated more commercial attention to its possibilities and advantages by organising an informative webinar about the benefits of reuse as part of our Sustainable FIBC Virtual Conference.

Our contributions

Our commitment to the Sustainable Development Goals (SDGs) as set by the United Nations:

Sustainable solutions 2020: 103-1, 103-2, 103-3

Strong potential for reuse

Potential for reuse in numbers

current vs. future

28 mln current potential

49 mln future potential

28 mln

49 mln

Benefits of reconditioning

By reconditioning 50,000 FIBCs in 2020, we were able to save up to 440,000 L if water, 285,000 kWh of energy, 120,000 kg of raw materials and 555,000 kg of CO2.

www.worldbag.com

More data in our 2020 Environmental Report.