LC Packaging’s most significant impact on the environment, society and economy occurs in our supply chain.

Sustainable production

Sustainable production

Supply Chain

We are actively improving the efficiency of our production processes to contribute to sustainable development. We want to ensure that our production facilities meet or even exceed the sustainability standards of our offices and warehouses. That is why independent research agency Except Integrated Sustainability conducts an annual environmental footprint research on our offices, warehouses and production facilities to measure our progress based on water and electricity use, waste production and CO2 emissions. Our goal is to improve our footprint in all four areas. A significant challenge – especially when looking at our use of recourses - as we also continue to expand our business with new employees, offices and production facilities.

Back to top

Scroll down

By 2022, we will have undertaken important steps to significantly improve the sustainability of our in-house manufacturing activities.

Target

continues to be a challenge with a 6% increase. This will be a focus area for the upcoming years during which a new building will be taken into use. The move to the newly built production facility brings a great opportunity to further green our production through solar energy and rain water harvesting among others. This was one of the main drivers for the move.

LC Shankar, our FIBC production facility in South Africa has taken significant steps in producing packaging in a more sustainable manner, among which was the repair of the water line feeding into the factory. Since 2016, LC Shankar decreased its energy usage by 77%, produced 92% less CO2 and limited its water usage by 77%. Waste production

Greening our production facilities

purpose of upcycling our process waste. In 2020, we recycled 425 MT PP process waste in-house. GREENBangla is one of the initiatives that has helped us reduce our waste production worldwide by 76% since 2016.

Third FIBC production facility in Bangladesh

Looking towards the future, we have started the build of the next phase of our expansion in Bangladesh, a third factory. The facility is expected to be operational by October 2021 and provides 4,000 square meters additional floor space, including a full-fledged cleanroom. The building is pre-fabricated steel to reduce the use of concrete and bricks, decreasing its environmental impact. The concrete and bricks used are purchased from a sustainable manufacturing producer. Additionally, we have invested in Zero-VOC paints on the walls, sensors to reduce water usage and the extensive use of insulation materials to reduce the amount of power required to ventilate the facility.

More data in our 2020 Environment Report.

At Dutch Bangla Pack Ltd. (DBPL) in Bangladesh, solar panels were installed to help supply the production facility with energy. DBPL had planned on implementing more solar panels in 2020 to generate about 15% of DBPL’s total energy requirement. The project was temporarily put on hold due to the COVID-19 pandemic. Additionally, the facility has saved 35% of water by replacing its traditional faucets with sensor controlled and auto-stopping faucets. Even though DBPL’s energy usage went up 17% in 2020 due to the opening of a second factory, it produced 55% less CO2 compared to 2019. Despite its efforts, the production facility’s water usage has increased by 61%, virtually the same as in 2019. Waste production is almost 0%, thanks to its in-house recycling initiative GREENBangla.

In 2018, we initiated a first-of-its-kind waste recycling project, together with our local Partners in Bangladesh: GREENBangla. Thanks to a state-of-the-art Starlinger Recycling Machine, 20 additional high-quality jobs were created for the

Plastic Recycling Initiative

Sustainable production 2020: 103-1, 103-2, 103-3

Introducing Dutch-Bangla Pack

Energy

C02

Water

Waste

Absolute increase/decrease 2016-2020

-77%

-92%

-72%

6%

Sustainable sourcing

Supply Chain

A sustainable supply chain is the integration of social, ethical and environmental performance factors into the process of selecting suppliers, producing products and delivering to customers. At LC Packaging, we train our employees to understand and make better-informed decisions that lead to more sustainable procurement and consumption. Next to its own manufacturing facilities, LC Packaging has approximately 80 Tier 1 suppliers (packaging producers), which we call our production partners. With these key partners – covering 80% of the sales – we have an average partnership of at least 25 years. 100% of our production partners is screened using environmental and social criteria.

Back to top

Scroll down

By 2022, 100% of our key production partners will have signed our Supplier Code of Conduct and will act accordingly.

Target

100% of our suppliers’ operations are covered by a risk assessment performed by LC Packaging. When it comes to risks occurring in regions or countries, we annually conduct a socio-political and geo location risk assessment based on the Amfori-BSCI Countries’ Risk Classification and the WorldRiskReport 2020. The risk assessment looks at the risks in a specific region or country. If a country is identified as high risk, it does however not automatically mean that the supplier is high risk as well. This of course also works the other way around: a high risk supplier could be located in a low risk country.

However, the risk assessment does provide valuable insights in the specific challenges our suppliers face. Additionally, a supplier’s specific risk score is calculated based on the risk score provided by the Sedex Supplier Risk Assessment Tool (Radar). Based on our risk assessment, 9 locations in which LC Packaging or its partners have operations are identified as a high risk location, being: Bangladesh, China, India, Indonesia, Ivory Coast, Pakistan, Sri Lanka and Vietnam. In 2020, 0% of our suppliers was identified as having a negative social or environmental impact.

The Supplier Selection and Assessment Process that was introduced in 2019, has been further implemented in 2020. In 2019 we were proud to share that 100% of our key suppliers have signed and comply with our code of conduct. This is still the case in 2020. At this moment, the final few suppliers are being administered to the programme. We aim to have all production partners aligned with our Global Supplier Code of Conduct by 2022.

GRI 308: 103-1, 103-2, 103-3

GRI 414: 103-1, 103-2, 103-3

Supplier selection

Extensive risk assessment

Curious how LC Packaging attempts to eliminate human rights violations and ensure good working conditions in the supply chain? Please watch the webinar ‘Human Rights: Preparing Business for What is to Come’, organised by the UN Global Compact and KPMG.

GRI 102-12

Sustainable partnerships 2020: 103-1, 103-2, 103-3

Sustainable partnerships

Supply Chain

Sustainable partnerships continue to be key to our success. We have always built long-term relationships with our stakeholders, ensuring stability and profitability. When it comes to our sustainable initiatives, our Partners our crucial.

Back to top

Scroll down

By 2022, we will have increased and strengthened our sustainable partnerships with our stakeholders and together, contributed significantly to achieving the goals.

Target

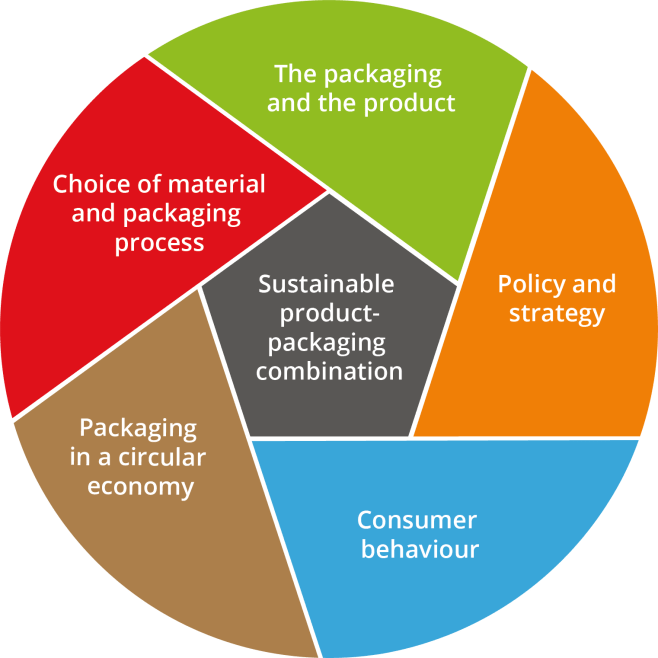

In 2020, we have established a new and important partnership with the Dutch Institute for Sustainable Packaging (KIDV). KIDV consists of a team of experts advising and inspiring companies with practical advise to make more conscious packaging decisions or make their packaging more sustainable. Together, we started a deep dive analysis of our packaging portfolio to decide on our sustainable journey on the short-term as well as the long-term. The analysis is partly based on the model ‘Five perspectives on sustainable packaging’®, designed by KIDV.

With the LC Supports Foundation we want to contribute to improving the welfare and environment of communities where LC Packaging is (in)directly present. With the help of our local partners, such as Grambangla, Happy Kids and Sri Lankan Hope for Children, we have set up wonderful projects. In 2020, we entered into a new partnership with the Wilderness Foundation Africa (WFA) to work on empowering vulnerable young people in South Africa with skills to help them with pathways to various livelihood opportunities.

Our Partners in capacity development, such as the FMO and the DEG, help us to create high quality jobs and stimulate economic growth, and our Production Partners are key in contributing to sustainable consumption and production and innovation.

LC Packaging GmbH, in Germany is now an official member of the PREVENT Waste Alliance. With this membership, we want to contribute to conserving resources and closing loops for packaging in close partnership with other members from the private sector, public institutions, academia and more.

The PREVENT Waste Alliance wants to contribute to minimising waste, eliminating pollutants and

maximising the reuse of resources worldwide. Organisations from the private sector, academia, civil society and public institutions jointly engage to create our circular economy. Together with other members, we will work on the prevention, collection and recycling – as well as the increased uptake of secondary resources – focusing on waste from plastic packaging and single use products.

In 2020, LC Packaging has become part of a joint initiative from industry organisations EFIBCA and Eurojute with the aim to establish a circular solution for FIBCs (big bags). Along with other leading FIBC producers and distributors a Circular Economy Working Group (CEW) was established. A unique collaboration where competitors in the industry join forces to find the perfect sustainable solution. The initiative will be continued in 2021.

On 19 November 2020, LC Packaging and its partners in sustainability have organised the sustainable FIBC Virtual Conference. Experts from EcoVadis, WorldBag, Starlinger, Veolia and Social Accountability International and LC Packaging informed, educated and involved LC Packaging’s customers about upcoming legislation, development and challenges related to recycling and reuse and working conditions. Because a truly sustainable packaging solution can only be established if all actors in the supply chain join forces, this event was organised to strengthen cooperation and understanding between those actors. Watch the sessions on-demand!

Aiming for circularity with Veolia

Learning and development with the Dutch Institute for Sustainable Packaging

Partners joining forces: FIBC Sustainable Conference

Partners in Community Development

Industry Initiative: Circular Economy Working Group

PREVENT Waste Alliance

In June 2019, LC Packaging and Veolia launched their Circular Pilot Programme to take the first steps towards a circular solution for FIBCs (big bags). Collecting the necessary volumes of used bags to be able to test washing and recycling methods turned out to be quite a logistical challenge. That is why, in January 2020, the FIBC Recycling Initiative was launched with the sole purpose to collect used LC Packaging bags in Germany and The Netherlands. Today, a truly circular solution is not yet established. Nevertheless, important steps have been taken, resulting in learnings, developments and

achievements. In our pilot programme, 19,000 kg of virgin raw materials has been saved. As well as 799,000 litres of water, 669,000 MJ energy and 48,000 kg of CO2 emissions. Based on the amount of recyclable bags distributed by LC Packaging, we see a potential of resource savings of at least X1,000. This translates to a potential of saving 22,562,500 virgin raw materials (PP/PE).

More on learnings, achievements and challenges is presented during the webinar ‘Design for Recycling and Recycling for Design’. Watch on-demand.

Our contributions

In our daily operations, LC Packaging has a direct impact on Global Sustainable Development Goals (SDGs) 8,9, 12 and 17 as set by the United Nations. However, we are committed and proud to contribute to even more of the SDG's through our actions and initiatives.

LC Packaging’s most significant impact on the environment, society and economy occurs in our supply chain.

Target

By 2022, we will have undertaken important steps to significantly improve the sustainability of our in-house manufacturing activities.

Sustainable production

We are actively improving the efficiency of our production processes to contribute to sustainable development. We want to ensure that our production facilities meet or even exceed the sustainability standards of our offices and warehouses. That is why independent research agency Except Integrated Sustainability conducts an annual environmental footprint research on our offices, warehouses and production facilities to measure our progress based on water and electricity use, waste production and CO2 emissions. Our goal is to improve our footprint in all four areas. A significant challenge – especially when looking at our use of recourses - as we also continue to expand our business with new employees, offices and production facilities.

Greening our production facilities

In 2018, we initiated a first-of-its-kind waste recycling project, together with our local Partners in Bangladesh: GREENBangla. Thanks to a state-of-the-art Starlinger Recycling Machine, 20 additional high-quality jobs were created for the purpose of upcycling our process waste. In 2019, we recycled 737 mt of polypropylene, which is 80% of our process waste. GREENBangla is one of the initiatives that has helped us reduce our waste production worldwide by 60% since 2017.

Plastic Recycling Initiative

At Dutch Bangla Pack Ltd. (DBPL) in Bangladesh, solar panels were installed to help supply the production facility with energy. DBPL had planned on implementing more solar panels in 2020 to generate about 15% of DBPL’s total energy requirement. The project was temporarily put on hold due to the COVID-19 pandemic. Additionally, the facility has saved 35% of water by replacing its traditional faucets with sensor controlled and auto-stopping faucets. Even though DBPL’s energy usage went up 17% in 2020 due to the opening of a second factory, it produced 55% less CO2 compared to 2019. Despite its efforts, the production facility’s water usage has increased by 61%, virtually the same as in 2019. Waste production is almost 0%, thanks to its in-house recycling initiative GREENBangla.

In 2018, we initiated a first-of-its-kind waste recycling project, together with our local Partners in Bangladesh: GREENBangla. Thanks to a state-of-the-art Starlinger Recycling Machine, 20 additional high-quality jobs were created for the

Sustainable production 2020: 103-1, 103-2, 103-3

Our contributions

In our daily operations, LC Packaging has a direct impact on Global Sustainable Development Goals (SDGs) 8,9, 12 and 17 as set by the United Nations. However, we are committed and proud to contribute to even more of the SDG's through our actions and initiatives.

Energy

CO2

Water

Waste

-77%

-92%

-72%

6%

Absolute increase/decrease 2016-2020

purpose of upcycling our process waste. In 2020, we recycled 425 MT PP process waste in-house. GREENBangla is one of the initiatives that has helped us reduce our waste production worldwide by 76% since 2016.

Third FIBC production facility in Bangladesh

Looking towards the future, we have started the build of the next phase of our expansion in Bangladesh, a third factory. The facility is expected to be operational by October 2021 and provides 4,000 square meters additional floor space, including a full-fledged cleanroom. The building is pre-fabricated steel to reduce the use of concrete and bricks, decreasing its environmental impact. The concrete and bricks used are purchased from a sustainable manufacturing producer. Additionally, we have invested in Zero-VOC paints on the walls, sensors to reduce water usage and the extensive use of insulation materials to reduce the amount of power required to ventilate the facility.

More data in our 2020 Environment Report.

Target

By 2022, 100% of our key production partners will have signed our Supplier Code of Conduct and will act accordingly.

Sustainable sourcing

A sustainable supply chain is the integration of social, ethical and environmental performance factors into the process of selecting suppliers, producing products and delivering to customers. At LC Packaging, we train our employees to understand and make better-informed decisions that lead to more sustainable procurement and consumption. Next to its own manufacturing facilities, LC Packaging has approximately 80 Tier 1 suppliers (packaging producers), which we call our production partners. With these key partners – covering 80% of the sales – we have an average partnership of at least 25 years. 100% of our production partners is screened using environmental and social criteria.

100% of our suppliers’ operations are covered by a risk assessment performed by LC Packaging. When it comes to risks occurring in regions or countries, we annually conduct a socio-political and geo location risk assessment based on the Amfori-BSCI Countries’ Risk Classification and the WorldRiskReport 2020. The risk assessment looks at the risks in a specific region or country. If a country is identified as high risk, it does however not automatically mean that the supplier is high risk as well. This of course also works the other way around: a high risk supplier could be located in a low risk country.

The Supplier Selection and Assessment Process that was introduced in 2019, has been further implemented in 2020. In 2019 we were proud to share that 100% of our key suppliers have signed and comply with our code of conduct. This is still the case in 2020. At this moment, the final few suppliers are being administered to the programme. We aim to have all production partners aligned with our Global Supplier Code of Conduct by 2022.

GRI 308: 103-1, 103-2, 103-3

GRI 414: 103-1, 103-2, 103-3

Supplier selection

Extensive risk assessment

Our contributions

In our daily operations, LC Packaging has a direct impact on Global Sustainable Development Goals (SDGs) 8,9, 12 and 17 as set by the United Nations. However, we are committed and proud to contribute to even more of the SDG's through our actions and initiatives.

However, the risk assessment does provide valuable insights in the specific challenges our suppliers face. Additionally, a supplier’s specific risk score is calculated based on the risk score provided by the Sedex Supplier Risk Assessment Tool (Radar). Based on our risk assessment, 9 locations in which LC Packaging or its partners have operations are identified as a high risk location, being: Bangladesh, China, India, Indonesia, Ivory Coast, Pakistan, Sri Lanka and Vietnam. In 2020, 0% of our suppliers was identified as having a negative social or environmental impact.

Curious how LC Packaging attempts to eliminate human rights violations and ensure good working conditions in the supply chain? Please watch the webinar ‘Human Rights: Preparing Business for What is to Come’, organised by the UN Global Compact and KPMG.

Sustainable partnerships

By 2022, we will have increased and strengthened our sustainable partnerships with our stakeholders and together, contributed significantly to achieving the goals.

Target

Sustainable partnerships continue to be key to our success. We have always built long-term relationships with our stakeholders, ensuring stability and profitability. When it comes to our sustainable initiatives, our Partners our crucial.

In June 2019, LC Packaging and Veolia launched their Circular Pilot Programme to take the first steps towards a circular solution for FIBCs (big bags). Collecting the necessary volumes of used bags to be able to test washing and recycling methods turned out to be quite a logistical challenge. That is why, in January 2020, the FIBC Recycling Initiative was launched with the sole purpose to collect used LC Packaging bags in Germany and The Netherlands. Today, a truly circular solution is not yet established. Nevertheless, important steps have been taken, resulting in learnings, developments and achievements. In our pilot programme, 19,000 kg of virgin raw materials has been saved. As well as 799,000 litres of water, 669,000 MJ energy and 48,000 kg of CO2 emissions. Based on the amount of recyclable bags distributed by LC Packaging, we see a potential of resource savings of at least X1,000. This translates to a potential of saving 22,562,500 virgin raw materials (PP/PE).

More on learnings, achievements and challenges is presented during the webinar ‘Design for Recycling and Recycling for Design’. Watch on-demand.

GRI 102-12

Sustainable partnerships 2020: 103-1, 103-2, 103-3

Aiming for circularity with Veolia

In 2020, we have established a new and important partnership with the Dutch Institute for Sustainable Packaging (KIDV). KIDV consists of a team of experts advising and inspiring companies with practical advise to make more conscious packaging decisions or make their packaging more sustainable. Together, we started a deep dive analysis of our packaging portfolio to decide on our sustainable journey on the short-term as well as the long-term. The analysis is partly based on the model ‘Five perspectives on sustainable packaging’®, designed by KIDV.

Our contributions

In our daily operations, LC Packaging has a direct impact on Global Sustainable Development Goals (SDGs) 8,9, 12 and 17 as set by the United Nations. However, we are committed and proud to contribute to even more of the SDG's through our actions and initiatives.

Learning and development with the Dutch Institute for Sustainable Packaging

Partners joining forces: FIBC Sustainable Conference

On 19 November 2020, LC Packaging and its partners in sustainability have organised the sustainable FIBC Virtual Conference. Experts from EcoVadis, WorldBag, Starlinger, Veolia and Social Accountability International and LC Packaging informed, educated and involved LC Packaging’s customers about upcoming legislation, development and challenges related to recycling and reuse and working conditions. Because a truly sustainable packaging solution can only be established if all actors in the supply chain join forces, this event was organised to strengthen cooperation and understanding between those actors. Watch the sessions on-demand!

Partners in Community Development

With the LC Supports Foundation we want to contribute to improving the welfare and environment of communities where LC Packaging is (in)directly present. With the help of our local partners, such as Grambangla, Happy Kids and Sri Lankan Hope for Children, we have set up wonderful projects. In 2020, we entered into a new partnership with the Wilderness Foundation Africa (WFA) to work on empowering vulnerable young people in South Africa with skills to help them with pathways to various livelihood opportunities.

Our Partners in capacity development, such as the FMO and the DEG, help us to create high quality jobs and stimulate economic growth, and our Production Partners are key in contributing to sustainable consumption and production and innovation.

In 2020, LC Packaging has become part of a joint initiative from industry organisations EFIBCA and Eurojute with the aim to establish a circular solution for FIBCs (big bags). Along with other leading FIBC producers and distributors a Circular Economy Working Group (CEW) was established. A unique collaboration where competitors in the industry join forces to find the perfect sustainable solution. The initiative will be continued in 2021.

Industry Initiative: Circular Economy Working Group

PREVENT Waste Alliance

LC Packaging GmbH, in Germany is now an official member of the PREVENT Waste Alliance. With this membership, we want to contribute to conserving resources and closing loops for packaging in close partnership with other members from the private sector, public institutions, academia and more.

The PREVENT Waste Alliance wants to contribute to minimising waste, eliminating pollutants and maximising the reuse of resources worldwide. Organisations from the private sector, academia, civil society and public institutions jointly engage to create our circular economy. Together with other members, we will work on the prevention, collection and recycling – as well as the increased uptake of secondary resources – focusing on waste from plastic packaging and single use products.