GRI 301-1, 301-2

Actions

One of the first and most important steps taken in our journey towards circular packaging, is the establishment of an in-house Innovation and Circular Economy Team. This team works closely with the product management, quality, supply chain, sales, and marketing teams to ensure the circular product innovation needed to achieve our goal. In terms of governance, a steering committee has been appointed to guide the strategy, consisting of the full Board of Directors and the Head of Sustainability.

Based on among others product CO2e lifecycle assessments (LCAs), our team has developed a sustainable innovation road map for all LC Packaging’s main product categories.

Read more on the product LCAs conducted.

Big Bags reuse, recycling and recycled content

Circular

Economy

2%

7%

Our goal to make our packaging circular by 2030, touches upon 6 out of 8 Sustainable Packaging Criteria

In base year 2021, 16% of turnover came from circular packaging.

Baseline

By 2030, at least 80% of our turnover comes from packaging that delivers the circular economy.

Goal

2022 was the year of gaining knowledge and understanding, conducting research, target setting, and (re)shaping our infrastructure and approach towards product innovation.

Last year, 18% of turnover came from packaging that delivers the circular economy. This is a 2% increase compared to base year 2021.

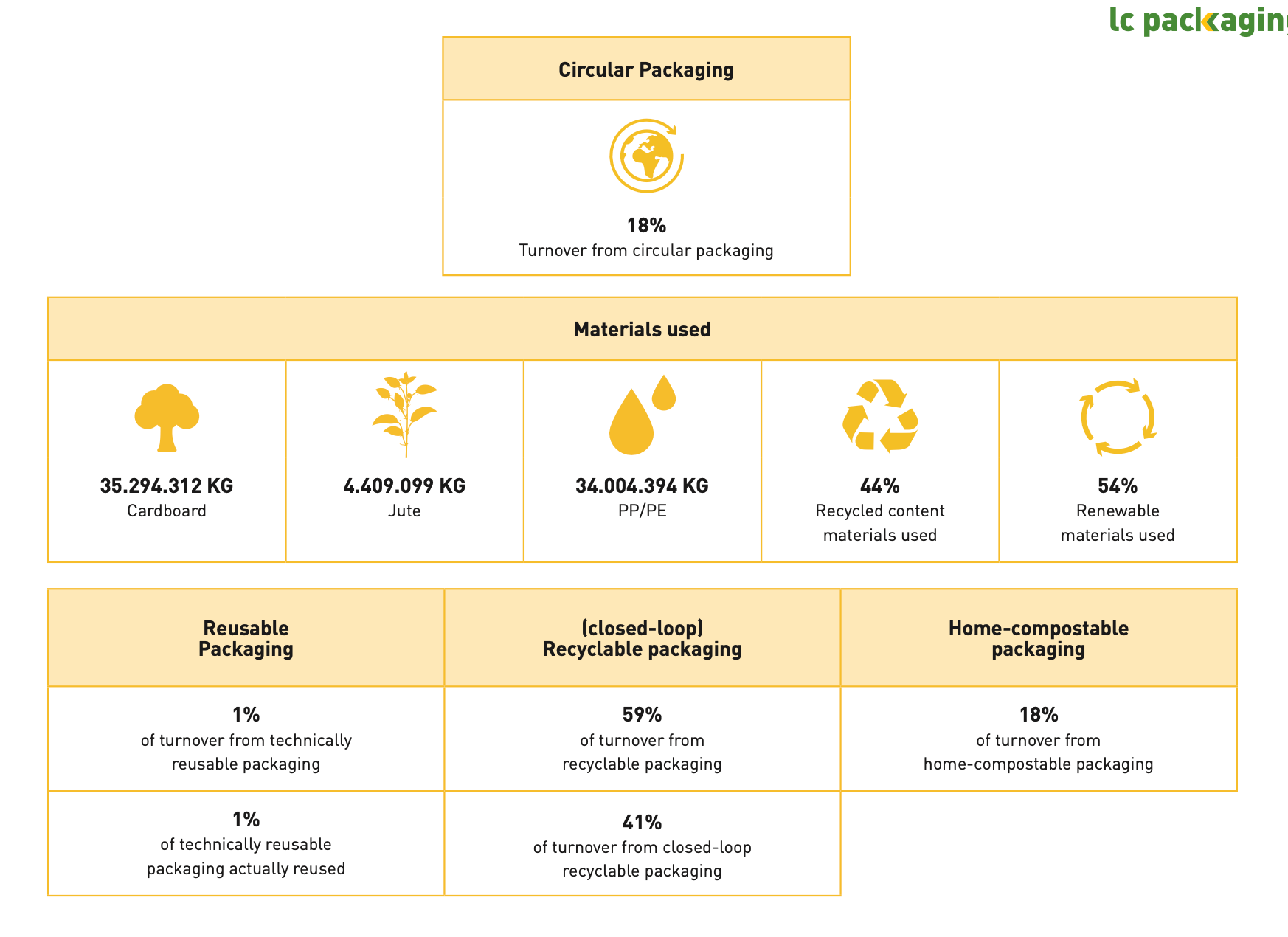

The graphic below presents an overview of the 2022 results and the first progress made.

Please note: These results are based on calculations including LC Packaging’s primary product categories, representing 86.1% of the total kilos of materials used, and 95.9% of the company’s total turnover in 2022.

Progress on goal

Included in the scope of this goal are LC Packaging’s main product categories; carboard packaging and paper bags, jute bags, FIBCs (big bags), woven PP bags and net bags. In 2022, these product categories represent 95.9% of LC Packaging’s total turnover.

Scope

Packaging made out of renewable materials or recycled content materials, that is reusable if possible, and 100% recyclable (preferably closed-loop) or compostable.

Definition circular packaging

LC Packaging aims to annually improve the availability and quality of data related to the material use and circular economy criteria. Compared to the 2021 report, definitions have evolved, due to having obtained more knowledge on the actual reusability, recyclability and composability of many of our packaging products, and due to market developments. As data availability and quality has improved significantly, the data for 2021 has been recalculated and rectified.

A summary of the results:

In 2022, 18% of turnover came from circular packaging, compared to 16% in 2021.

In 2022, LC Packaging sold 512 mln, pcs of packaging, compared to 510 mln. in 2021. However, fewer kilos of materials were used: 73,7 mln in 2022, compared to 78 mln. in 2021.

The turnover from packaging made from renewable materials and from packaging including recycled content materials both increased by 3%.

In 2022, 3% more recycled content materials was used in our packaging, partly because LC Packaging distributed its first FIBCs (big bags) that included Post-Consumer Recycled (PCR) rPP. read more

In 2022, 39% of distributed packaging was recyclable. A decrease of 1% compared 2021, due to an increase in distributed baxmatic jute bags. The percentage of distributed closed-loop recyclable packaging remained the same at 33%.

A distinction has been made between 'non-reusable packaging', 'technically reusable packaging' and 'packaging that is actually reused': packaging purchased for reuse. Almost 4 million pcs of packaging distributed in 2022 were categorised as technically reusable, of which 1% was actually reused through LC Packaging's WorldBag reuse programme (representing 2% of turnover from technically reusable packaging). By investing heavily in WorldBag, we are confident we will experience a gradual annual increase of turnover from actually reused packaging in the upcoming years.

For more detailed information on the materials used in our packaging, and the circularity of our packaging portfolio,

please refer to our 2022 Environmental Report.

Explanation

For more detailed information on the materials used in our packaging, and the circularity of our packaging portfolio, please refer to our 2022 Environmental Report.

2022 Environmental Report

2022 Environmental Report

01

01

Policies, codes, and commitments

02

Awareness and

implementation

03

Research and

development

04

Data and

reporting

LC Packaging has become an official member of Plastic Pact NL and is committed to its 2025 goals.

Policies, codes, and commitments

A new Code of Conduct for Key Production Partners was drawn up and presented to the first group of production partners. This code includes a requested commitment to contribute to the circular economy ambition.

LC Packaging’s reuse service WorldBag joined the New European Reuse Alliance (New ERA) as founding member, aiming to raise awareness among relevant EU and national policymakers to establish the required infrastructure, incentives and rules to accelerate the transition from single-use to reuse.

New partnerships have been explored and established, such as our partnership with Healix, aimed at producing high quality rPP made from Post-Consumer Recycling (PCR) materials that can be used to produce new FIBCs (big bags)

Next steps

As looking forward is even more important than looking back, below is a brief overview of actions we are planning to take next.

Based on among others the CO2e Product Lifecycle Assessments, set product category targets for 2030, and short- and long-term sustainable sales KPIs in order to boost low-emission product innovation and the sales of these products.

Ensure progress towards our goal is made, by running the sustainable product innovation projects set up in 2022 and 2023, and further develop our product innovation approach.

Further improve data quality and availability leading to more reliable data for circular economy reporting and decision making.

Committed

© 2023 LC Packaging

www.lcpackaging.com

7%

2%

GRI 301-1, 301-2

LC Packaging aims to annually improve the availability and quality of data related to the material use and circular economy criteria. Compared to the 2021 report, definitions have evolved, due to having obtained more knowledge on the actual reusability, recyclability and composability of many of our packaging products, and due to market developments. As data availability and quality has improved significantly, the data for 2021 has been recalculated and rectified.

A summary of the results:

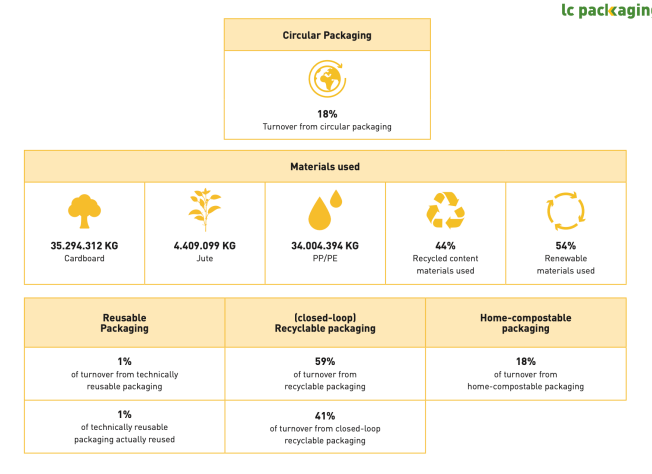

In 2022, 18% of turnover came from circular packaging, compared to 16% in 2021.

In 2022, LC Packaging sold 512 mln, pcs of packaging, compared to 510 mln. in 2021. However, fewer kilos of materials were used: 73,7 mln in 2022, compared to 78 mln. in 2021.

The turnover from packaging made from renewable materials and from packaging including recycled content materials both increased by 3%.

In 2022, 3% more recycled content materials was used in our packaging, partly because LC Packaging distributed its first FIBCs (big bags) that included Post-Consumer Recycled (PCR) rPP. read more

In 2022, 39% of distributed packaging was recyclable. A decrease of 1% compared 2021, due to an increase in distributed baxmatic jute bags. The percentage of distributed closed-loop recyclable packaging remained the same at 33%.

A distinction has been made between 'non-reusable packaging', 'technically reusable packaging' and 'packaging that is actually reused': packaging purchased for reuse. Almost 4 million pcs of packaging distributed in 2022 were categorised as technically reusable, of which 1% was actually reused through LC Packaging's WorldBag reuse programme (representing 2% of turnover from technically reusable packaging). By investing heavily in WorldBag, we are confident we will experience a gradual annual increase of turnover from actually reused packaging in the upcoming years.

For more detailed information on the materials used in our packaging, and the circularity of our packaging portfolio,

please refer to our 2022 Environmental Report.

Circular

Economy

Our goal to make our packaging circular by 2030, touches upon 6 out of 8 Sustainable Packaging Criteria

In base year 2021, 16% of turnover came from circular packaging.

Baseline

By 2030, at least 80% of our turnover comes from packaging that delivers the circular economy.

Goal

Included in the scope of this goal are LC Packaging’s main product categories; carboard packaging and paper bags, jute bags, FIBCs (big bags), woven PP bags and net bags. In 2022, these product categories represent 95.9% of LC Packaging’s total turnover.

Scope

Packaging made out of renewable materials or recycled content materials, that is reusable if possible, and 100% recyclable (preferably closed-loop) or compostable.

Definition circular packaging

2022 was the year of gaining knowledge and understanding, conducting research, target setting, and (re)shaping our infrastructure and approach towards product innovation.

Last year, 18% of turnover came from packaging that delivers the circular economy. This is a 2% increase compared to base year 2021.

The graphic below presents an overview of the 2022 results and the first progress made.

Please note: These results are based on calculations including LC Packaging’s primary product categories, representing 86.1% of the total kilos of materials used, and 95.9% of the company’s total turnover in 2022.

Progress on goal

Explanation

Actions

One of the first and most important steps taken in our journey towards circular packaging, is the establishment of an in-house Innovation and Circular Economy Team. This team works closely with the product management, quality, supply chain, sales, and marketing teams to ensure the circular product innovation needed to achieve our goal. In terms of governance, a steering committee has been appointed to guide the strategy, consisting of the full Board of Directors and the Head of Sustainability.

Based on among others product CO2e lifecycle assessments (LCAs), our team has developed a sustainable innovation road map for all LC Packaging’s main product categories.

Read more on the product LCAs conducted.

01

02

03

04

New partnerships have been explored and established, such as our partnership with Healix, aimed at producing high quality rPP made from Post-Consumer Recycling (PCR) materials that can be used to produce new FIBCs (big bags)

LC Packaging’s reuse service WorldBag joined the New European Reuse Alliance (New ERA) as founding member, aiming to raise awareness among relevant EU and national policymakers to establish the required infrastructure, incentives and rules to accelerate the transition from single-use to reuse.

LC Packaging has become an official member of Plastic Pact NL and is committed to its 2025 goals.

A new Code of Conduct for Key Production Partners was drawn up and presented to the first group of production partners. This code includes a requested commitment to contribute to the circular economy ambition.

Policies, codes,

and commitments

LC Packaging established an in-house Innovation and Circular Economy Team, ensuring the circular product innovation needed to achieve our goal.

The Sustainable FIBC Virtual Conference 2022 was organised to invite our customers to join us in our quest to close the loop on circular packaging and to present the business case.

Through dedicated workshops on LC Packaging’s 2030 Ambition, in which 94% of all employees participated, for each business process (e.g., sales, logistics, HR, quality, production etc), ways to contribute towards achieving our goals have been identified and translated into short- and long-term targets and KPIs.

A dedicated mandatory online training course has been launched for our employees, explaining LC Packaging’s circular economy commitment. The course was launched in May 2022 and has a completion rate of 80.3%.

Awareness

and implementation

To create the environmental business case for circular packaging, LC Packaging has developed a Carbon Footprint Calculator for FIBCs together with our partner The Footprinters, showing the CO2e savings when using recycled materials or switching to reuse.

As an active member of the EFIBCA/EuroJute Circular Economy working group, LC Packaging has a contributed to a [Draft] Design for Recycling Industry Standard, creating the basis for the development of a circular economy for the FIBC (big bag) industry.

Read more

Research

and development

To improve data quality and availability related to among others the sustainability of our packaging, a Data and Reporting Analyst was appointed, which has already resulted in improved reporting data on the weight of materials used and circular economy criteria.

Read 2022 Environmental report

Data

and reporting

Big Bags reuse, recycling and recycled content

Next steps

As looking forward is even more important than looking back, below is a brief overview of actions we are planning to take next.

Based on among others the CO2e Product Lifecycle Assessments, set product category targets for 2030, and short- and long-term sustainable sales KPIs in order to boost low-emission product innovation and the sales of these products.

Ensure progress towards our goal is made, by running the sustainable product innovation projects set up in 2022 and 2023, and further develop our product innovation approach.

Further improve data quality and availability leading to more reliable data for circular economy reporting and decision making.

For more detailed information on the materials used in our packaging, and the circularity of our packaging portfolio, please refer to our 2022 Environmental Report.

2022 Environmental Report

2022 Environmental Report

© 2023 LC Packaging

www.lcpackaging.com